Mastering CAT 3500B/3500C Engine Sensors: Location, Function ( in 10 minutes)

Download information and video details for Mastering CAT 3500B/3500C Engine Sensors: Location, Function ( in 10 minutes)

Uploader:

Diesel DecodedPublished at:

7/25/2025Views:

568Description:

Master the electronic sensor system on the Caterpillar 3500B and 3500C marine engines with this comprehensive guide. This video provides an in-depth look at each sensor, clearly explaining its location, core function, and its role in communicating with the ECM. This video is specifically designed for marine engineers, heavy-duty diesel technicians, and maintenance managers looking to enhance their diagnostic and repair skills for CAT engines. Learn how sensor signals directly impact engine power, fuel consumption, and reliability. Gain the knowledge to read electrical schematics, accurately identify component locations, and understand the root cause of common DTC fault codes. VIDEO CHAPTERS (CLICK ON TIMESTAMPS TO JUMP): 00:00 Introduction to Engine Sensors 01:13 Inlet manifold temperature sensor 02:05 Turbo inlet pressure sensors 02:51 Turbo outlet pressure sensor 03:26 Aftercooler temperature sensor 03:58 Atmosph pheric pressure sensor 04:30 Crankcase pressure sensor 05:36 Oil temperature sensor 06:15 Oil pressure sensors 06:54 Engine coolant temperature sensor 07:29 Fuild pressure sensors 08:32 Thermocouple 09:10 Turbo exhaust temperature sensors 09:45 Primary/Secondary speed and timing sensors 10:49 Magnetic pickup sensor Thank you for watching! If you found this video helpful, please LIKE, SUBSCRIBE, and leave a COMMENT with any questions. Contact: #CAT3500 #MarineEngine #DieselEngineRepair #Caterpillar #MarineEngineering

Video Transcription

Welcome to the Deep Dive.

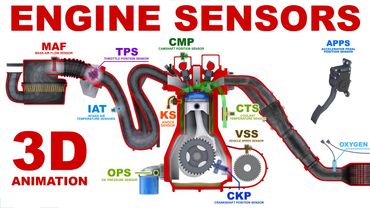

Today we're diving deep into the pretty intricate world of engine sensors.

Yeah, it's fascinating stuff.

It really is.

If you think of an engine as like a highly evolved organism, these sensors are truly its nervous system.

They're constantly gathering vital information, feeding it back to the brain, which is the engine control module or ECM.

That's a great analogy.

So our mission in this deep dive is to sort of pull out the critical insights from our sources, really revealing how essential these often overlooked components are.

We'll look at their specific roles, their impact, and the precise data that keeps an engine running smoothly.

And efficiently and safely too.

Exactly.

You might not actively think about them much, but these tiny sensors, they're the real unsung heroes.

They make sure your engine can adapt to changing conditions, protect itself from potential damage, and even subtly warn you when something isn't quite right.

the real aha moment here i think is understanding that these sensors aren't just you know reporting problems after they happen they're giving the engine a kind of sixth sense right allowing it to adapt and prevent issues before anyone even knows something's wrong it's uh it's proactive prevention really okay let's unpack this let's start where every engine begins with air how an engine breathes is

well fundamental managing that airflow precisely is absolutely key for both power and efficiency yeah so our first stop is the inlet manifold temperature sensor it's placed quite strategically after the turbocharger compresses the air and the aftercooler cools it down it measures the air temp right before it goes into the engine

And why there?

Well, that specific temperature is crucial because the ECM uses it to calculate air density, which is critical for getting that perfect fuel to air mix inside the combustion chamber.

Our sources show this sensor operates within a surprisingly narrow range sometimes, maybe just an 18 degree Fahrenheit window.

Wow, that tight.

Yeah, it really highlights just how sensitive those calculations need to be for optimal performance.

Okay, following that, we've got the left and right turbo inlet pressure sensors.

Now, these are positioned before the air even gets to each turbocharger.

Right.

And the clever bit here is that these sensors act as sort of early warning systems.

By monitoring the air pressure before the turbo, they can tell you about the air filter's condition.

If you see a big drop in pressure or like a high vacuum reading, that's a pretty clear sign the filter might be clogged up.

Restricting airflow.

Exactly.

potentially hurting turbo performance.

These sensors, they usually report pressure between say 52 and 71 inches of mercury.

Gotcha.

So we've seen how air gets into the turbo, but what about once it's compressed?

That high pressure air, it needs measuring too, right?

Absolutely.

And that's the job of the turbo outlet pressure sensor or the boost pressure sensor.

Same thing.

Makes sense.

This one measures the air pressure after it leaves the turbo.

The ECM uses this reading to, well, fine tune the turbo's performance, making sure the engine gets just the right amount of compressed air for whatever it's doing at that moment.

Right.

Depending on the load.

Exactly.

Now, our source didn't give specific numbers for this one, but its importance is really in its dynamic role.

It's constantly telling the ECM, here's the boost level, allowing those real time tweaks.

Maximizing power, but also protecting the turbo itself.

Precisely.

Protecting it from overboosting.

Okay.

Crucially, after the turbo, that hot compressed air needs cooling again for maximum density.

That's where the aftercooler temperature sensor comes in.

Yep.

It measures the temperature after the air has gone through that aftercooling process.

And this confirms the aftercooler is doing its job effectively.

You got it.

Getting that air as cool and dense as possible ensures the best charge enters the combustion chamber, which again translates directly to efficient power.

Our sources suggest this temperature generally needs to stay below about 109 degrees Fahrenheit.

Okay.

Then there's the atmospheric pressure sensor.

Does what it says on the tin, I suppose.

Measures the ambient air pressure around the engine?

Exactly.

The ECM uses this as like a baseline.

Think of it as the engine's altimeter.

Ah, clever.

By subtracting this atmospheric pressure from the boost pressure reading we just talked about, the ECM figures out the true boost.

And then it automatically adjusts things for efficient performance, whether you're down at sea level or way up high in the mountains.

So it gives it context.

Precisely.

Constant environmental context.

And finally, for air management, we have the crankcase pressure sensor.

This one measures pressure inside the engine's crankcase, which isn't an area you might immediately think about.

Right.

But if that pressure gets too high, it's a direct signal for something called blow-by.

Blow-by.

Yeah.

It's when combustion gases, instead of pushing the pistons down, actually sneak past them and into the crankcase.

It's a clear sign of internal wear, maybe worn piston rings or cylinder liners.

Ah, okay.

Not good.

Definitely not good.

Our sources suggest a typical operating range here is incredibly narrow, maybe four to plus four inches of water.

So any deviation is significant.

It's really a key indicator of the engine's internal health.

So when you look at all these air sensors together.

What you're doing is giving the engine this precise atmospheric awareness, letting it optimize its own breathing in real time, adapting to a dirty filter or climbing a mountain pass.

It's pretty sophisticated.

Absolutely.

OK, let's move from air to the engine's vital fluids, oil and fuel.

These sensors are kind of like internal medical checkups, constantly monitoring those critical liquids.

Let's start with the engine oil temperature sensor.

OK.

This one monitors the lubricating oil's temperature.

Why is that so critical?

Well, if the oil gets too hot, it starts to break down.

It loses its viscosity, its ability to lubricate properly.

Which could cause serious damage.

Exactly.

Severe engine damage.

So the ECM will watch this, and if it gets too high, it'll throw a warning or maybe even derate the engine to cut back its power just to protect those vital components.

Our sources say a typical max temp is around 221 degrees Fahrenheit.

That makes sense.

But it's not just about temperature, is it?

How does the system know if the oil filter is clogged?

That could also cause big problems.

Right.

And that's where the oil pressure sensors come in.

Specifically, you usually have two, one measuring filtered pressure and one measuring unfiltered.

OK, so before and after the filter.

Exactly.

The filter sensor tells you the actual pressure being supplied to things like bearings.

The unfiltered sensor measures it before the filter by comparing those two readings.

The ECM can see the pressure drop across the filter.

Precisely.

If the drop is too big, it knows the filter is restricted and needs changing.

It's a really clever proactive check, prevents oil starvation issues.

Our sources mentioned a typical pressure range between, say, 22 psi minimum and maybe 87 psi maximum.

Very nice.

Okay, next up.

The engine coolant temperature sensor.

This tracks the temperature of the coolant circulating through the engine.

Yeah, this is another really core parameter.

The ECM uses it mainly to control the cooling fan system.

Turning it on when needed.

Right.

And crucially, if the engine starts to seriously overheat, the sensor reading triggers warnings or, in extreme cases, even an emergency shutdown to prevent meltdown.

Our sources cite a maximum around 210 degrees Fahrenheit.

Okay.

And just like with the oil, there's a similar check for the fuel system.

Yep, exactly the same principle.

You've got the fuel filter pressure sensors, again, usually a filtered and an unfiltered one.

Before and after the fuel filter.

Correct.

Filtered pressure shows what's actually going to the injection system.

Unfiltered shows what's coming from the tank.

Compare the two.

And you know if the fuel filter's clogged.

You got it.

Detects restrictions, flags it for service, prevents fuel delivery problems that could, you know, leave you stuck on the side of the road.

Our sources list typical fuel pressure between about 44 PSI minimum and 87 PSI maximum.

It's amazing how these fluid sensors provide such real-time diagnostics.

It really is like monitoring the engine's lifeblood.

It absolutely is, preventing those potentially catastrophic failures before they even get a chance to start.

Okay, this next category, this really drives home that nervous system analogy we started with.

Because here, the sensors aren't just reporting single data points.

They're giving us this incredibly detailed, real-time health readout.

We're talking about the sensors that dictate the engine's rhythm, its timing, and crucial safety functions.

First up, the thermocouples, 1 through 16.

16 individual temperature sensors.

Yes, 16.

One for each cylinder's exhaust gas temperature.

These are incredibly important for advanced diagnostics.

How so?

Well, if one cylinder's exhaust temperature is significantly different from the others, maybe much hotter, maybe much colder, it's a strong indicator of a problem specifically in that cylinder.

It could be an injector issue, a valve problem, something wrong with the combustion process right there.

So it pinpoints the fault.

Exactly.

Very granular fault detection.

Our sources indicate a typical maximum exhaust manifold temperature somewhere around 1076 degrees Fahrenheit.

That's pretty hot.

That is hot.

Okay, complementing those, we have the left and right turbo exhaust temperature sensors.

These measure the exhaust gas temp entering each turbocharger's turbine.

Right.

This helps monitor the overall engine load.

But more critically, it protects those delicate turbine wheels from excessive heat damage.

Turbos work hard, they get very hot.

Makes sense.

Our sources show a typical maximum exhaust temperature after the turbo, like in the outlet stack, maybe around 859 Fahrenheit.

Still hot, but less than the manifold.

Yeah.

Some heat energy has been used to spin the turbo by then.

Right.

Okay.

Then we get to the primary and secondary speed and timing sensors.

These sound really important.

Oh, they are absolutely critical.

This pair reads signals.

Usually from a toothed wheel on the crankshaft or maybe the camshaft.

They tell the ECM two fundamental things.

The engine speed, its RPM, and its precise rotational position at any given millisecond.

And that position data is key for timing.

Absolutely foundational.

Yeah.

The ECM uses that position data to control the fuel injection timing with incredible precision, making sure fuel sprays in at the exact right moment for efficient combustion.

And why primary and secondary?

A backup.

It's exactly redundancy.

If the primary sensor fails, which can happen, the ECM just seamlessly switches over to the secondary sensor signal.

The engine keeps running, reliability is maintained, it's vital.

So no specific parameters like temperature or pressure, they just need to work within the engine speed range?

Correct.

They just have to accurately report speed position from, say, a low idle around 650 RPM up to the high idle speed, maybe 1730 RPM or whatever the engine's limits are.

We also have a magnetic pickup sensor.

What's this one typically for?

That's another type of speed sensor.

Often its main job is just to provide an RPM signal directly to, say, the tachometer on your dashboard.

Ah, for the driver's information.

Right.

Our sources didn't list specific parameters here either, likely because its role is less about precise control calculations and more about providing that basic speed reading or confirming rotation.

Okay.

Next, the proximity sensor.

This one is tied to a critical safety device, the air shutoff valve.

Yes.

The air shutoff valve is designed to stop the engine in an emergency.

For instance, if an engine somehow starts ingesting external fuel like flammable gas in the air, it can start to run away, revving uncontrollably.

This valve slams shut, cutting off the air supply to stop it.

Oh, okay.

So this proximity sensor's job is simply to confirm the position of that valve.

Is it fully open for normal operation?

Or is it securely closed in an emergency?

It reports that status back to the ECM.

Making sure that safety system is ready and working.

Exactly.

Again, it's more about confirming a state open or closed rather than a variable reading.

So specific parameters aren't usually listed.

Right.

And finally, the timing calibration sensor.

This sounds like something for maintenance.

Precisely.

It's a specialized sensor used mainly by technicians.

It allows them to very accurately calibrate or time the engine, meaning they ensure the ECM's electronic understanding of timing perfectly matches the actual physical mechanical position of the pistons, crankshaft, and camshaft.

It's about fine-tuning that synchronization for long-term health and peak performance.

Wow.

Okay.

So, yeah, this whole network of timing and diagnostic sensors, it really highlights how you get such fine-grained control and how you get early warnings for even really subtle combustion issues.

It's all about that precision and that redundancy working together.

Extending engine life, preventing costly downtime.

Absolutely.

So what does this all really mean for you listening in?

We've taken quite a deep dive into this incredible world of engine sensors.

We've seen how these small but mighty components act as the eyes, the ears, even the pulse of an engine.

Yeah, from managing that perfect breath of air.

Right, to safeguarding the vital fluids, ensuring that precise timing.

They're continuously feeding the ECM the data it needs to keep everything running optimally and safely.

What we've really seen is that the true hero isn't just one sensor, but the whole data network they create.

That invisible real-time conversation happening constantly inside the engine.

Keeping it fine-tuned and hopefully out of the repair shop.

Exactly.

And the sheer volume, the specificity of the information these sensors provide, it just underscores how intricate modern engines are.

It kind of makes you think about how critical data collection is for any complex system to work well.

That's a great point.

Not just engines.

Not just engines, no.

Think about software, logistics networks, even biological systems.

That constant feedback is key to efficiency and avoiding unexpected failures.

So for you, our listener, maybe something to ponder.

Where else in your daily life do you think these kinds of hidden sensors or data points are quietly at work, influencing outcomes, ensuring safety, maybe without you even realizing their constant vigilance?

Yeah, it's happening all around us.

It really is a lot to think about.

Similar videos: Mastering CAT

Engine Sensors - Basics. 3D Animation

Metal Gear Solid Delta - Ultimate Guide for Stealth and Combat

Осциллограф или Мотортестер. Что выбрать автоэлектрику (для новичков)?

SMD Components EXPOSED: SMD Transistor & Diode Test in Seconds 🔥🔥🔥 Part 2

RC Car Xtra Speed XS01 SCX10 1967 Chevy C10 Off-Road Bash Rock Crawling