World’s Toughest Flights | The Ice Plane: Crossing the Arctic | Free Documentary

Download information and video details for World’s Toughest Flights | The Ice Plane: Crossing the Arctic | Free Documentary

Uploader:

Free DocumentaryPublished at:

4/13/2025Views:

680.4KDescription:

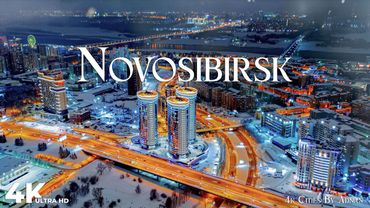

World’s Toughest Flights | The Ice Plane: Crossing the Arctic | Free Documentary Floating Super Clinic - Secrets of the Mega Hospital Ship: She's the "Workhorse of the North," powering through the vast Arctic region, where conditions can turn deadly in seconds. Nolinor Aviation's 737-200 C is a combination cargo and passenger aircraft, delivering essential food, equipment, and workers to Meadowbank, the coldest mine on Earth. The gold mine depends on this super hauler four times a week, but common temperatures of minus 50 degrees often wreak havoc on the aircraft and her missions. Follow her on a typical job, which poses challenges that are anything but routine. ▬▬▬▬▬▬▬▬▬ Subscribe Free Documentary Channel for free: Instagram: Facebook: Twitter: ▬▬▬▬▬▬▬▬▬ #FreeDocumentary #Documentary #plane ▬▬▬▬▬▬▬▬▬ Free Documentary is dedicated to bringing high-class documentaries to you on YouTube for free with the latest camera equipment used by well-known filmmakers working for famous production studios. You will see fascinating shots from the deep seas and up in the air, capturing great stories and pictures of everything our extraordinary planet offers.

Video Transcription

She's the workhorse of the North.

It's hard.

It's harsh.

It's cold.

It's windy.

It's extreme.

Engine stable.

950 is on the roll.

Flying to the most unforgiving place on Earth.

Now we go up north.

That's where the men are separated from the boys.

Boeing 737-200C, the best combination aircraft for Arctic flying.

Sometimes you need more cargo, and some other day you need more people to go in.

servicing the world's coldest gold mine.

Without that plane, we would be having a very, very difficult time.

Two weeks from now when I see that plane coming in, I couldn't be happier.

Where conditions can turn deadly in seconds.

It is a one-shot deal, and there's no room for mistakes.

Mirabel Airport near Montreal, Quebec, home to the powerful 737-200C.

The 737 is the best-selling commercial jetliner in history.

She's the go-to aircraft for short-haul flights throughout North America and Europe.

Her pilot is Bruno Saint-Jacques.

It's a good airplane.

It's one of the best airplanes in the world.

We can carry cargo and personnel.

And as well, the airplane is quite fast.

All right, first leg here from here to Val d'Or, Mirabel to Val d'Or, 49 minutes.

This morning, Bruno and co-pilot Jean-Christophe Seguin prepare their next mission for Nolanoor Aviation, a charter airline servicing the most rugged terrain in the world.

Today, they will be delivering essential food, equipment and workers to a booming gold mine in the Arctic.

Very good weather, although cold.

So for the kind of job we're doing, it's the perfect plan.

We can go on the gravel with a jet so we can fly high, we can fly fast, and we can land on a small strip.

And that's pretty much what's all about the North.

This mission is one of four weekly flights to Meadowbank Gold Mine in Nunavut.

Without the plane, the mine would shut down.

Yeah, we are lifeline to go to Meadowbank.

It's important because every hour they're losing, they're losing money.

And it's not in terms of a few bucks.

It's about sometimes in terms of $10,000 that they're losing every time the mine is shut down.

There's no other way to get there besides the airplane.

After departing Mirabel, Nolenor's 737 will fly to Val d'Or, Quebec to pick up workers and essential supplies before continuing to Meadowbank gold mine in Nunavut.

Sky clear in Meadowbank and six miles vis plus.

Winds are 290, 18 knots.

Looks good, sky clear all the way and no turbulence in high altitudes.

But flying close to the North Pole, the weather can change in an instant.

Anything could happen because Baker Lake is so near Meadow Bank.

It's only 40 miles.

And it's advertising two miles in ice crystal, blowing snow.

So we might get some of it or none at all.

We'll know once we get there.

It's generally safe.

No, it's good.

If any pilot understands the challenge of flying in this vast region, it's Bruno.

I have 22,000 hours flying up north, and that's where I live.

That's where I am, up north.

Last week, we were delayed three days because the weather was so bad.

There was a wind up to 40 knots, which is about 55 miles an hour with snow.

In Nolenor's hangar, flight engineer Savas Alexiou reconfigures the 737 for today's cargo.

5,400 kilograms of food, three pallets of machinery, and 57 passengers.

The guys and me are removing the wall that basically separates the cabin and the cargo so we can get more space out of it.

Today's shipment has extra cargo.

That means losing 18 passenger seats.

So we're going to end up being able to put three pallets instead of two, so we can make sure that the important cargo is going to come on board.

This 737-200C is a combination cargo and passenger aircraft, or combi for short.

measuring almost 30 meters long, over 11 meters high, with a wingspan of 28 meters.

When transporting cargo and passengers, this super hauler can be configured for seven pallets of full cargo, 120 all passenger seating, or any combination in between.

You could have cargo of any size, any form, put it in as well as bring in passengers that they need.

That's what makes it different, this aircraft compared to the other one.

The 737 is almost good to go.

Today's shipment is heading 2,300 kilometres north to Meadowbank Gold Mine.

Metal Bank produces millions of dollars of gold every year.

We mine approximately 30 million tons of rock in a year.

Out of that, a little over 4 million tons is ore.

Inside the mine's warehouse, shipping manager James Bost prepares for the plane's arrival.

The 737 is critical to the mine.

Everything depends on what comes into the plane.

We can't just go to the corner store and buy

Today, James is waiting for a key piece of equipment the gold miners have got to have.

We have a bit sharpening machine that had a major problem with it.

Actually, it doesn't work anymore.

That's very critical for the mine.

We sharpen maybe 100 bits per day here.

But without the sharpening machine, rotary drills can't drill holes for explosives to break up the rock.

Without that machine, things will stop in the pit.

Keeping this place running 24-7 is a tall order.

Temperatures of 40 degrees below zero and over 120 kilometer per hour winds wreak havoc with production.

The weather we have here, the extreme cold weather, is very hard on parts.

So things do break more often than other locations.

James is also waiting for three hydraulic cylinders for a damaged excavator.

So these cylinders are a pretty important part at the moment for an excavator that needs them.

Without it, workers won't be able to scoop up over 80,000 metric tons of blasted rock a day.

But it takes more than machines to keep this place in operation.

A kilometer from the warehouse, Meadowbank's kitchen is already in full swing.

Hello.

Hello.

Today I'm waiting for milk, carrots, celery, tomatoes, all our fresh vegetables.

Everything's coming in today.

Nolenor's 737 delivers a pallet of fresh food every week.

Without it, Meadowbank's kitchen shuts down, and Richard has an army to feed.

We're responsible for feeding 450 to 500 people a day, so it's 1,500 meals a day that we're serving, plus snacks and even between meals.

You know, you're trying to give people quality of life.

They're away from home two weeks at a time, three weeks at a time.

One of the only comforts they have here is food.

Richard is counting on today's food shipment to feed tonight's hungry crowd.

All of the mine supplies come from Val-d'Or, Quebec, 1,900 kilometers southeast.

At Val-d'Or Airport, warehouse clerk Marlène Leclerc packs up Meadowbank's pallet of fresh groceries.

It's all foods.

We don't know what is in each, but it's food.

This is a clip to hold it in place.

If it moves, it will hold the whole package together.

While Marlène makes sure the mine gets the food they need, logistics coordinator Denis Caron gets them their equipment.

Denis takes stock of the machinery for today's flight.

He has everything he needs, except the drill bit sharpening machine.

Meanwhile, at Mirabel Airport, the 737 is fully reconfigured and ready to go.

But Savas's job is far from over.

He's also the flight engineer on today's mission.

We're basically bringing our toolbox so we can do whatever job we need to do up north, because down there, there's no spare parts, there's no spare mechanic.

In the cold, anything could break, so we just got to make sure we're good and we're able to fix it.

But the plane isn't the only thing susceptible to the Arctic chill.

You cannot survive if you're not dressed well enough in the Upper Canada region.

It's impossible.

This flight has a strict dress code.

Crew and passengers must fly with extreme cold weather gear.

When you've got a minus 40 temperature and 35 knots across, that wind in your face.

I have ski goggles.

That's pretty good.

Those ones, when you've got a blizzard and a full face, that's a must, the full face.

If you don't got that, you're going to freeze out there.

Their bags are packed.

They got the crew tags, so it should be good.

And they're ready to go.

Cabinets secure.

All right.

Here we go.

Four takeoff.

Four takeoff flaps.

Jet stable.

Set takeoff thrust.

Takeoff thrust set.

80 knots.

Check.

V1.

Rotate.

Positive rate.

Get up.

Flaps up.

Noltenor's 737 takes to the skies right on schedule, 7 AM sharp.

Her first destination is Val d'Or Airport in Quebec.

This leg is a quick 50-minute hop, with only five minutes spent flying at altitude.

The thing is, a jet, you want to go high and fast, but you don't want to burn your fuel staying low.

For us, it's a rush because as soon as you're done taking off here, you already think about the descent and the approach.

We'll just cancel the IFR with Montreal.

We're going for the runway 36.

And we'll be there in about 10 minutes.

The 737 is on its final approach to Val d'Or.

But on the ground, Denis Caron is missing a vital piece of cargo for Meadowbank.

The drill bit sharpening machine hasn't arrived.

And if Nolenor's 737 doesn't deliver it today, work in the pit could come to a standstill.

In Western Quebec, this 737 is on a mission to bring vital equipment and workers to a remote Arctic gold mine.

Landing checklist engine, start switches.

Learning, Chef.

Speed brake.

Speed brake, on green light.

Landing checklist complete.

First stop, Val d'Or Airport to pick up its entire payload.

During that time, we need to load the cargo, to fuel, load the luggage.

Everybody got his job to do.

If we do it right, we can make a quick turnaround.

But on the ground, in the airport's warehouse, a vital piece of mining equipment is missing.

Logistics coordinator Denis Caron tracks down the drill bit sharpening machine.

Salut, Yves, Denis.

If the 737 doesn't deliver it to Metal Bank today, mining in the pit will grind to a halt.

There's 10 minutes left before the plane arrives.

My part should arrive in about 10 minutes as well.

So everything should coincide as planned.

The part will be on the plane this morning.

Heading up the loading effort is Director of Cargo Denis Heroux.

Apart from the machinery, we load the plane, the luggage, and so on.

And we do it as quickly as possible so that the plane is less time-consuming.

Danique gets a jump start on the rest of the cargo.

The plane is minutes from touching down.

First up, a week's supply of food for 500 mine workers, double-wrapped for freshness.

Next, the mining equipment.

Perfect.

The hydraulic cylinders are needed for a broken excavator at Meadowbank Mine.

In the airport's terminal, the gold miners wait for today's flight.

And at least one of them is ready to get back to work.

Well, I just finished days off.

Been a good two weeks at home, spent New Year's at home.

Now we're going back to work, back in the really cold.

Gonna have some fun.

I'll break machines.

Up above, the 737 is on final approach.

I'm gonna descend on the low.

Check.

Gear down.

Captain Bruno Saint-Jacques takes her in for landing.

80 knots, 60 knots.

First line of business, refuel the plane.

Even though the flight to Baldor was under an hour, the 737 flies high and fast, and she's a gas guzzler.

Now, flight engineer Savas Alexiou readies the plane for today's load.

Time is ticking.

We want to see if the loose cargo is coming on board or not, and that's about it.

Co-pilot Jean-Christophe checks the status of the drill bit sharpening machine.

The sharpening machine is on site and almost ready for shipping.

On the tarmac, loading is underway through the 737's side cargo door.

It's one of the unique features of this combination aircraft.

Once the pallet is in place, it's latched down and locked to the floor.

A loose piece of cargo in flight could harm the 57 passengers seated behind this removable wall.

While the cargo is loaded in the front, passengers board at the back.

Next up, the drill bit sharpening machine.

And last, the three meter long hydraulic cylinders.

Right now, we're still waiting.

We're looking at the cylinders, see how we're going to load those.

Preparing them for shipment is taking time.

Denis feels the heat.

Takeoff is at 15 minutes.

Finally, the 180-kilogram cylinders are ready to go.

And we're going to bring them in by lift and manhandle them a little to place them in the flanks.

So we got them on board and that's what counts.

Denis operates the forklift.

One misstep could cause tens of thousands of dollars in damage.

It's really stressful for the operator because at any moment, the cylinder can hit a door.

The forklift closes in with Bruno and Savas on safety watch.

The boom arm of Denis' forklift comes dangerously close to striking the open cargo door.

Captain Bruno suggests a new plan of attack.

So that's the second position of our door.

There's two positions on it.

Canopy, which is the regular opening, and full canopy when we need the extra height and clearance.

It's a tight squeeze, maneuvering the three-meter-long cylinders to the plane's 3.3-meter opening.

Whoa, whoa, whoa.

Get there.

Check the boot of the pallet.

Getting them in place is only half the battle.

Now Savas needs them to stay put.

So we're just strapping down there and make sure it doesn't move on takeoff landing and all the way through the trip.

So since it's an odd type of material and not a basic pallet like this, it's just a little more complicated.

Yep.

Basically, this is the final step, the fire part.

It's a requirement since we have passengers.

We've got to make sure that if anything catches on fire or anything, we're safe, and this is going to contain it.

Cargo is secure, and the passengers are all aboard.

Pilots Bruno and Jean-Christophe need to get their wheels up.

This is where we're going to leave Val d'Or to Meadowbank.

We still have three hours.

somewhat 30 minutes to go of a flight at 32,000 feet.

They're on the move, despite reports of bad weather at Meadowbank.

Not too far from there, there is ice crystal forecasted and it might affect the visibility on the approach.

Set takeoff to us.

Engine stable.

Takeoff tower set.

950 is on the road.

Getting to the mine safely will mean pushing the plane and crew to their limits.

Val d'Or, Quebec, the pickup point for Nolanoor's 737 mission to the Arctic.

JL Center, good day, Nolanoor 950 off Val d'Or, 5,000 feet in the climb.

Fully loaded with vital supplies and workers, she begins a three and a half hour trek north to Meadowbank Gold Mine.

But bad weather is looming.

The weather can be really, really changing fast.

If we're taking off from Val d'Or, it could be sky clear in Meadowbank.

And by the time we get to the middle of the Hudson Bay, it's already down to the minimums.

Even in the best conditions, landing at the mine is a challenge.

The strip in Meadowbank is a pretty short deal.

You need to touch down at the right place.

It's a gravel strip, so you have to configure the plane.

We have to be sure that the braking action is good.

It's kind of a one-shot deal.

1,900 kilometres north at Meadowbank, road supervisor Stéphane Laroze helps make their landing a safe one.

So the airstrip is very short, and the aircraft has to stop very quick.

And we have to keep the airstrip in tip-top condition at all time.

Overnight, a thick layer of ice formed on top of the 1,500-meter airstrip.

Stéphane's grader breaks it up.

For the airstrip, we installed those spinner blades.

They are a lot better to increase the braking friction.

Without proper grip, the plane could overshoot the runway and land in the mining pit.

We're not only shoveling the airstrip, we break the ice, we turn the airstrip like paper sand.

Once the ice is broken up, airport controller Ghislaine Beaudoin tests the runway.

So that's what I'm doing now is getting prepared to do the runway friction index.

That's what I do first thing in the morning after checking what's the weather going to be like today.

Sensors located under the truck measure the surface braking friction.

So I'm going to go up to 45, then push the brakes hard, 45, 50 kilometers per hour.

OK, get ready.

As he steps on the brakes, the sensors measure the amount of friction.

So that gives me 41, which is good.

So when we're above, let's say, 30, we consider it to be a good braking action.

The airstrip is ready for touchdown.

Almost two hours into today's flight, Captains Bruno and Jean-Christophe reach a critical point in their mission.

9950 will report the ranking inlet VOR on the 1334.

We're just about to cross 60 parallel here, north 60.

So at this point, we're going to be in the northern space.

Crossing this invisible boundary, a line of latitude 60 degrees north of the equator can wreak havoc with the plane's compass.

Once we fly at 60 north and above, the magnetic instruments are not accurate enough for us to navigate with them.

A magnetic compass is the primary source of the aircraft's heading on the 737.

It uses the magnetic north pole to establish the plane's correct direction.

But due to changes in the Earth's magnetic field, the magnetic north pole is always shifting.

And 60 degrees north of the equator, the shift is more pronounced.

they switched their heading system to the true North Pole, a fixed point of longitude and latitude.

What we're going to do here, we're going to switch from mag to through.

And as you see here on the flight management system, everything is now in through.

Following true north provides the most accurate heading for northern navigation.

This precise information is needed in case of an emergency landing.

Up north, navigation is very important because you're very far from other runways that we are allowed to use.

There are some runways, but maybe too short for us.

Meanwhile, in the back of the plane, passengers are unaware of the pilot's efforts to keep them safe.

But everyone on board must come prepared for an Arctic emergency.

Their survival depends on it.

Yeah, we do have big Canada goose, boots, long johns, mitts, the whole, I don't know how you call it in English, but the whole thing that covers your face.

Yeah, we have to work with this because sometimes when you get stuck out there, there's no choice.

You have to work with it.

Minus 50 is quite cold.

Mine workers are no strangers to harsh conditions.

We had a blizzard that was three days long a week ago.

We had no fresh fruit.

We had very little good vegetables.

But life at Metal Bank has its sweet spots.

I really like working there because it's a challenge, for one.

And for two, it's really interesting, especially for what I do.

I do engineering, so I help to design the mine.

And it's very cool to see it from that perspective.

And happy people are better equipped to deal with working in Canada's coldest mine.

We have excellent facilities here to keep people mobile so they don't get little winter swelling around the middle.

We play floor hockey.

If not, we play badminton on a regular basis.

We have pool table and shuffleboard and everything upstairs.

Yeah, a lot of people can't believe the activities that we actually have up here.

You're out in the middle of the tundra playing underneath a tent, so to speak, playing badminton in the middle of nowhere.

And life doesn't get better than that.

While workers continue to enjoy their downtime,

In the skies over Nunavut, the pilots are starting their approach.

Jean-Christophe checks in with airport controller Ghislain Baldwin for the latest weather conditions.

Good day again, 9950.

Hello, we're in bounds at 75 miles southeast.

We're passing flight level 260.

The most important thing up north is the weather.

It will determine if you're going to make it or not.

I'm now 9-5-0 Meadowbank.

The surface wind is 3-0-0 at 15.

Temperature is minus 30.

The altimeter, 2-9-6-7.

So, latest weather.

Meadowbank, it's 17 Zulu.

3-0-0 at 20 knots.

Ice crystal, blowing snow.

Minus 30, minus 34, and 2-9-6-7.

A cloud of ice crystals is hanging over Meadowbank's airstrip, obstructing visibility below.

If we don't see the runway at 300 feet, radar altimeter, it's an automatic overshoot.

The pressure is on to get the 737 on the ground, safe and sound.

Above the Arctic Circle, a 737 combi loaded with vital supplies and passengers is preparing to land at Meadowbank Gold Mine.

What about the ice crystals?

Pretty much around, or it's getting better?

But the airstrip is obscured by a cloud of ice crystals.

If pilots Bruno Saint-Jacques and Jean-Christophe Seguin can't see the runway at 300 feet, they won't be able to land.

Visibility is critical when landing at the mine.

And the runway is short.

It's 5,400 feet.

So we need to touch down the first 1,000 feet.

And after that, stop there.

You only have a certain length of runway that you have to stop on because there's a ditch on both ends.

And it's a real eerie feeling.

I feel like I understand these guys when they talk about landing on an aircraft carrier because it's pretty much exactly what it is.

But finding the runway is only half the battle.

When their wheels touch down, loose gravel can puncture the fuselage.

That's why Nolanor's 737 comes equipped with a gravel deflector attached to the nose landing gear.

A 1.2 meter long deflector shields the underbelly of the aircraft from spraying gravel when taxiing on unpaved airstrips.

but there's no other jet airplane that can do the job that this airplane is doing.

At home base in Mirabel, Quebec...

Okay, gear down.

Gear down!

Mechanic Jason Falana-Leduc inspects a newly installed deflector on another 737 in Olinor's fleet.

Today we are going to test a full retraction extension cycle of the nose landing gear.

That's important to make sure that the ski doesn't interfere with the retraction after takeoff and with the extension for landing.

If it's not properly locked down, you can have a nose crash when you hit the ground, or if it's not going up properly when you're in the air, it's going to cause a lot of drag, so you're going to have to come back on the ground.

Okay, ready, Cedric?

Yep.

Hydronic!

And you see we've got a nice streamlined profile on the ski here, so that's perfect.

So all the gaps are good?

Yeah, all the gaps are OK. Everything is according to spec, so we're ready to go.

Awesome.

Perfect.

Good.

The deflector protects the fuselage from the flying gravel, but not the engines.

On the flight line, production manager Pierre Doré and his team test a second gravel protection device called the vortex dissipator.

All good?

Ready to go?

Yeah.

OK.

A small projecting pipe, or boom, blasts bleed air from the engines down and forward, preventing gravel from being sucked up by the engines.

Without it, the fan blades of the 737's jet engines would be destroyed.

technician are currently installing a pressure gauge so once the engine is going to be running we're going to turn the system on and off and they're going to check that the proper pressure from the engine is treated to the gravel detector booth so i'll need a marshall and i'll go crank up the engine

With engines at full throttle, the technicians check that the vortex dissipator blows air pressure over 20 psi in order to deflect the gravel.

So guys, all went?

All good?

Yep.

22 psi on opening.

And zero on closing.

Any leaks on the valve?

No leaks?

OK.

So you can remove all the test equipment, put the cap back on.

You double check.

Then we'll close the cowling.

We're good to go.

Awesome.

The Vortex dissipator is performing to spec.

This plane is ready to service the Great White North.

In the skies over Nunavut, Captain Bruno is ready to bring his bird in for a landing.

There's no room for error at all.

It is a one-shot deal.

One approach only, and then direct the alternate.

But the airstrip is still hidden below the cloud of ice crystals.

Bruno relies on his GPS to guide the plane towards the start of the runway.

Back on profile.

Minimums.

Check.

Landing.

As the 737 descends to 300 feet, it breaks out of the cloud of ice crystals, making it safe to land.

We're on speed on profile.

On speed.

Box minus five.

40, 30, 30, 10.

Speed brake up.

It's a spot-on touchdown.

50 knots.

60 knots.

The deflector does its job, shielding the 737's fuselage from flying debris.

Nice landing.

Thank you.

Flight engineer Savas shifts into high gear.

Oh, it's a cold one today.

Nice wind, too.

I guess we'll get this done quick.

We don't want to freeze.

An inspection ensures the plane is intact.

The plane's looking good.

Weather's cold, windy.

Minus 40 with the wind.

It's pretty cold out here.

Gloves are starting to freeze over.

The ground crew jumps into action.

Well, for me, the worst thing that can happen is we actually get a major mechanical where the plane can fly out the cargo or the passengers.

So the faster we're in and out, the better it is for us and the plane.

In this extreme cold, they need to move quickly.

Every second counts.

At Meadowbank, the coldest mine in the world, Nolenor's 737 is in a race against time.

Flight engineer Savas Alexiou needs a quick turnaround on the ground to ensure this plane can get back in the air.

We want to get out there as fast as possible.

It's because of the cold weather.

Engines get cold, the oil gets cold, so we have more chances of ice building up, blocking either gear retraction or flaps from going down.

First order of business, refueling the plane.

The 1,900-kilometer flight from Val d'Or, Quebec, has guzzled up nearly 13,000 kilograms of fuel.

She's running on empty, and she needs fuel now, even when parked.

Meanwhile, at the back, the passengers are quick to find shelter.

After two weeks off, it's not easy adjusting to 40 degrees below zero.

In the cargo bay, Savas doesn't waste a moment unloading the plane.

First off, the hydraulic cylinders for the broken excavator.

This time, the door is ready.

You can get in with that, because my door is wide open.

All right, guys, there's the part you needed.

The ground crew moves fast while keeping a close eye on the plane.

All right, he's good.

No, he can't turn anymore.

He's going to have to lift a little and back out.

It's pretty rough.

Everything's cold.

The metal's cold.

All the parts that you're handling are basically cold.

So if you're not wearing gloves, if you're not paying attention to frostbite and everything, you could get in trouble pretty fast.

The extreme cold is rough on people and machines.

So after 2,000 hours of northern flight, repairs are mandatory.

In Mirabel, Quebec, another Nolanor 737 is undergoing heavy maintenance work.

This airplane has been operating up north for a while, so has suffered a lot from heavy landing, short runway, gravel operation, very, very cold weather operation.

So now we're going through a structural inspection.

With the 737 stripped to its rivets, mechanic Olivier Gauthier takes stock of the damage inside the fuselage.

It's a worst-case scenario.

A crack in the airframe compromises the plane's structural integrity, making it too dangerous to fly.

Also from the inspection, we found a big damage here on the tail section.

So it was a big dent, most probably from a rock.

The battered section has been cut out.

Now the aircraft's skin needs to be repaired.

Every parts are fabricated here in the sheet metal shop.

We have to form every single part for the repair.

We have all the machines, all the tools.

Sheet metal made of aluminum alloy is used to patch the hole.

They're shaping the part for the fuselage contour.

We call that an English wheel that stretches the metal.

It's then cut to precise measurements.

45.

All right, so we'll cut it at around 50.

OK, let's go.

Bring it.

This 737 has already undergone 2,000 hours of work, but another 1,500 hours of overhaul is still required before it can return to the skies.

In a few months, this plane will be back servicing the north.

At Meadow Bank, Savas and his team push through with the unloading so they can get back up in the air fast.

The much anticipated drill bit sharpening machine is next up.

Just watch until he comes, because it's going to slide.

And finally, the palette of fresh food is on its way to the kitchen.

For Chef Richard Jackson, the food can't come soon enough.

This is our fresh produce coming in.

Food comes in from the plane, comes right into our loading dock, and then we send it off to the fridges to get stocked.

So minus 40 degree weather plus wind chill, minus 60, fresh produce doesn't last very long at all.

Richard is happy that his produce didn't freeze while on the airstrip.

Keeping a fully stocked kitchen is important up here.

We're going to be having milk, cheese, yogurt, eggs, fresh fruit, fresh vegetables.

We pull through about 900 liters of milk a week.

We get about 12,000 pounds of food a week, fresh food that's coming on the plane every week.

Without this regular delivery, supplies dwindle.

We have had times we've come very close to running out where you run out of certain things where you got to be a little creative and sort of make up for it, so.

Hi, Andre.

Hi.

How are you?

I'm good.

With hundreds of hungry workers to feed today, the produce flown in on the 737 is already on the cutting boards.

So everything that would come in on the plane, most of the fresh vegetables, this guy will be responsible for preparing them, cooking them, heating them up, and getting them out served to the customers.

Half a kilometer from the kitchen, James Bost is on standby in Metal Bank's warehouse.

the cylinders for the broken excavator are first to arrive.

Everybody's going to be happy we got this one.

He'll ship them straight to the maintenance garage, where they'll be installed in the excavator.

This is our bit sharpening machine that everybody's anxious to get.

We'll get it unpacked and get it where it needs to go so they can get it up and running.

OK, Caleb, you know where this goes.

They're waiting for you.

With that new sharpening machine, the work in the pit will soon get back up to speed.

On the airstrip, Savas is still under the gun.

He's got to load the southbound cargo, and time is running out.

In 15 minutes, the mine will blast over 45,000 kilograms of rock out of the earth, creating a huge dust cloud over the airstrip, compromising visibility on takeoff.

We don't wanna get stuck there because they got a time that they're gonna do blasting, so we try to get out before the blasting for safety reason.

In these extreme conditions, the pilots can't afford to wait for the dust to settle.

At Metal Bank Gold Mine in the Arctic, a 737 has 10 minutes to take off and complete her mission.

A scheduled blast in the open pit could delay departure and put the plane at risk of a mechanical breakdown from the extreme cold weather.

Going to need somebody on there.

Bring it out on that safety brush.

The ground crew hurry, but this truck engine, flying home for service, is giving them a hard time.

Captain Bruno lends a hand.

We not only bring equipment in, but we take the broken equipment out from there, because a mine uses a lot of equipment and it breaks down.

When you have to crush rock, it's metal against rock, and sometimes the metal would break down.

So that part has to be replaced, and that's what we do.

Go and step on the other end.

In Meadowbank's cafeteria, Chef Richard is keeping his customers happy.

Well, what's on the menu today is we have flank steaks, and it's a real winner with the guys here.

For steaks, we have to have, you know, 450, 500 steaks ready to serve.

Cooked as fresh as we can get them.

Out on the airstrip, Bruno and the ground crew get the job done with minutes to spare before the blast.

Before they take off, Savas has one final inspection to make sure nothing is cracked or broken.

I think it's looking good.

It's frozen over, but it's good.

56 workers have punched out and are heading home for the next two weeks.

Bruno's team has pulled through.

It's a real good feeling because they need everything that we bring here.

Now we've done our job, we're going back home.

Traffic 267 at Meadowbank, 99.951 at Boeing 737.

We're taxiing for departure runway 302 from Meadowbank.

We'll do a left turn going southeastbound to Baldor, 99.951.

Full takeoff checklist complete.

Okay.

Set takeoff thrust.

Past 80 knots.

Check.

V1, VR.

It's a perfect takeoff into the skies above Meadowbank.

The Arctic might be an unforgiving place to work, but the 737 makes it all possible.

So the 37 is really a workhorse.

You know you're in the right aircraft for the kind of job and the kind of condition that we got in the Arctic.

Tomorrow, they'll fly the same route all over again.

The gold mine depends on it.

It's been flying up north for at least the last 40 years.

It proved itself to be the best to do the job.

The rugged 737-200 combi, a lifeline to the Arctic for many years to come.

Thank you.

Similar videos: World

USAF doesn’t want stealthy drones, despite China's stealth fleet. Why?

360° U-2 Spy Plane Flight | Full Cockpit Ride to 70,000 Feet

9/11: One Day in America | MEGA EPISODE | National Geographic

Ayahuasca With “The Dragon of The Jungle" | FULL Documentary

The Deadly Photograph that Won Kevin Carter a Pulitzer Prize